Learn more about working principle of desiccant rotary wheel dehumidifier

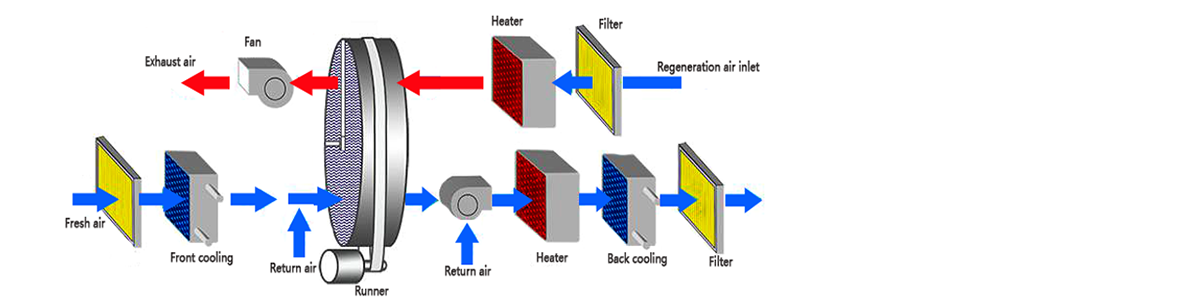

Desiccant rotary wheel dehumidifier is one of the most widely used solid adsorption dehumidification technologies in practical engineering.The rotary dehumidifier uses the good hydrophilicity of the absorbent material to absorb the moisture in the air and reduce the humidity of the air. The rotary dehumidifier is composed of dehumidifying wheel, transmission device, fan, filter, and heater for regeneration.

The working principle and characteristics of the desiccant dehumidifer

The core component of the desiccant dehumidifier is a honeycomb wheel. The wheel is composed of a special ceramic fiber carrier and active silica gel. Both sides of the wheel are divided into two areas by a special sealing device, the treatment area and the regeneration area. When the humid air that needs to be dehumidified passes through the treatment area of the runner, the water vapor of the humid air is absorbed by the active silica gel of the runner, and the dry air is sent to the space to be treated by the treatment fan; and the slowly rotating runner carries the trend Because saturated water vapor enters the regeneration zone; the high temperature air blown in the regeneration zone in the reverse direction causes the adsorbed moisture in the runner to be desorbed and is discharged outside by the fan, so that the runner restores the moisture absorption function and completes the regeneration process. The wheel continuously rotates, and the above-mentioned dehumidification and regeneration are performed cyclically, so as to ensure the continuous and stable dehumidification state of the dehumidifier.

Adsorption medium for desiccant dehumidification technology

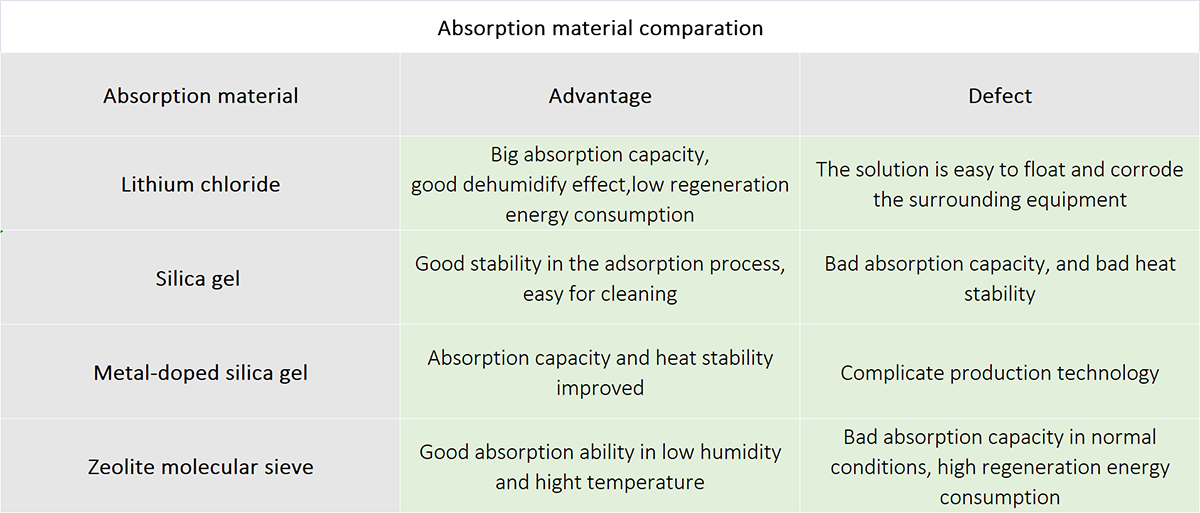

Lithium chloride was first used as an adsorbent for rotary dehumidifiers. It belongs to a kind of hygroscopic salt with high moisture content, which is easy to regenerate and has a high degree of chemical stability. In addition, the lithium chloride adsorbent has a strong sterilization ability. Therefore, as a dehumidifier, lithium chloride is widely used in fields that require high air cleanliness and humidity, such as medicine and food. However, lithium chloride has a small amount of dehumidification and low dehumidification capacity in the low humidity range, and it is easy to form a liquid when it absorbs moisture and escape from the substrate, causing corrosion to the metal around the dehumidification equipment. These shortcomings have largely limited the chlorination in the dehumidifier. The amount of lithium adsorbent also limits the dehumidification capacity of the dehumidifier.

Silica gel is a solid adsorbent that has been studied and applied more after lithium chloride. Its moisture absorption capacity and regeneration energy consumption are slightly worse than lithium chloride. However, because it always maintains a solid state during the adsorption and desorption process, it has good physical properties. The chemical stability overcomes the shortcomings of the lithium chloride adsorbent that is easy to liquefy and escape, and it can keep the surface of the runner without condensation even under high humidity (100%), and there is no corrosion to the surrounding equipment. At the same time, when the dehumidification efficiency of the runner is affected by dust or oil covering the surface during long-term use, it can be directly washed with water (to remove dust) or detergent (to remove oil) to restore it, so it has been widely used.

Modified silica gel: At present, there are two main aspects to the modification of silica gel: one is to combine traditional silica gel adsorbents and halogen salts to make a composite adsorbent; the other is to dope other metal elements in silica gel.

Zeolite molecular sieve is a solid adsorbent material with more research and application. Its excellent performance in absorbing moisture under low humidity environment makes it very suitable for low dew point and deep dehumidification; on the other hand, even at higher temperatures (such as 100 ~ (120°C) molecular sieve still maintains a water absorption rate of more than 13%, while the water absorption rate of silica gel is almost zero. Therefore, molecular sieve dehumidification is widely used in electronic, precision instruments and other conditions where the humidity requirements are very low and the ambient temperature is high. The dehumidifier of the rotary dehumidifier using molecular sieve can reach the lowest air dew point at the outlet of -60 ℃.

Practical application of desiccant dehumidification technology

The application scope of the runner dehumidification technology involves many aspects of the production and storage of pharmaceuticals, aviation, lithium batteries, electronics, supermarkets, candy, glass, film, etc.

(1) Air humidity adjustment. Such as the dehumidification of various types of warehouses, production workshops with temperature and humidity requirements, underground projects and cabins;

(2) Sterilization. Because some dehumidifiers (such as lithium chloride) have a strong bactericidal effect and can kill more than 90% of the bacteria in the processed air, they can be used for ventilation and dehumidification in the pharmaceutical industry, food industry, and sterile rooms;

(3) Projects requiring low humidity. If used in conjunction with refrigeration technology, it can easily obtain a low dew point air below 40 ℃;