The True Cost of Dehumidifiers: Why Energy Efficiency Matters for Long-Term Savings

When shopping for dehumidifiers, the market offers a wide range of options with varying prices, quality, performance, and energy efficiency. While the upfront cost of a dehumidifier is often the primary focus, it’s essential to consider the total cost of ownership. This includes factors like long-term electricity consumption, durability, and energy efficiency, which determine the overall expense of running one or multiple dehumidifiers over a year or even several years.

Dehumidifiers from different manufacturers are designed for specific use cases, and their operating costs can vary significantly depending on the environment. For example, in agricultural settings such as plant cultivation, dehumidifiers must operate continuously for extended periods while maintaining high energy efficiency. This ensures a dry environment that promotes proper plant transpiration. However, standard ceiling-mounted dehumidifiers, optimized for environments around 30°C, struggle to perform efficiently in cultivation settings where temperatures typically hover around 26°C. While they may still remove moisture, their efficiency drops significantly, often leading to issues like frost buildup and excessive energy consumption.

To meet the unique demands of grow room environments, we’ve developed the E-Series Grow Room Dehumidifiers. These units are built with premium materials and feature a 1.5 times larger heat exchanger, maximizing the efficiency of the compressor for the same cooling capacity. The expanded evaporator surface area allows for greater moisture condensation, while the larger condenser surface area improves heat dissipation, reducing the compressor’s energy consumption.

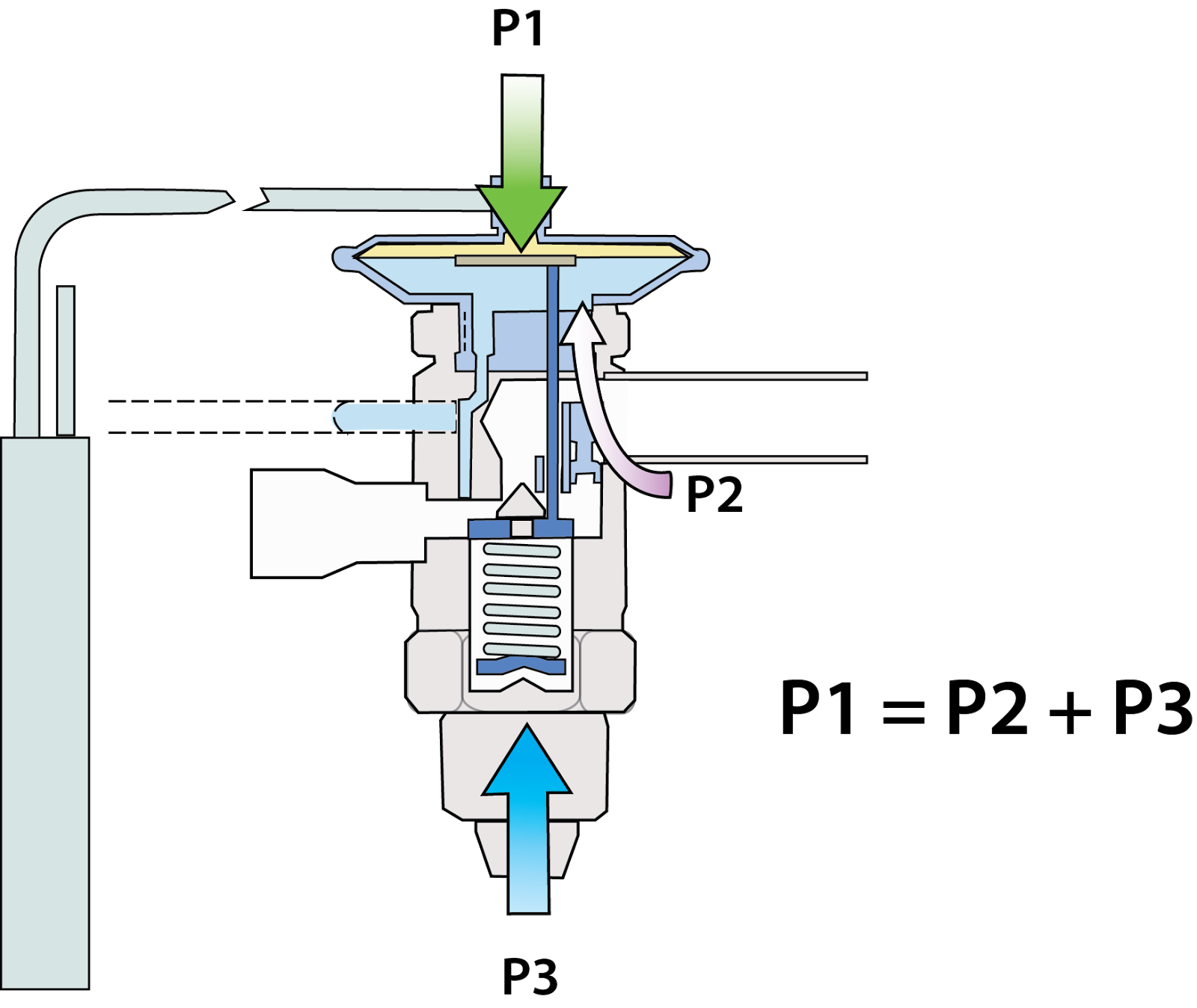

Additionally, our dehumidifiers are equipped with a specialized expansion valve designed specifically for dehumidification, unlike those used in air conditioners. This valve precisely controls the evaporator temperature to optimize condensation, rather than merely facilitating heat exchange (as the superheat requirements differ between the two applications). In contrast, many standard ceiling dehumidifiers use capillary tubes for throttling, which are far less efficient in controlling evaporator temperature compared to expansion valves.

These differences in core refrigeration components highlight the superior performance and efficiency of our E-Series Cultivation Dehumidifiers compared to conventional models. In future posts, we’ll explore other components that set our dehumidifiers apart, ensuring you have a comprehensive understanding of what makes them the ideal choice for specialized environments like agriculture.

By investing in a dehumidifier designed for your specific needs, you not only save on energy costs but also ensure reliable, long-term performance—making it a smarter choice for both your wallet and your operations.